XYZ Inspection by 3P Services

XYZ inertial measurements

The high-end inertial systems that 3P uses for the XYZ modules deliver accurate position data of the pipeline, both as a horizontal map (X- and Y-components) and the vertical profile. Combined with marker positions above ground these data can be processed to geographic co-ordinates for each girth weld, installation or feature identified by other ILI technologies. The resulting data base usually reaches an accuracy of better than +/- 1m horizontally when an individual pipeline must be located.

Compact information about our XYZ inspection

This page gives you an overview about the following topics:

The Physical Background of XYZ inspection

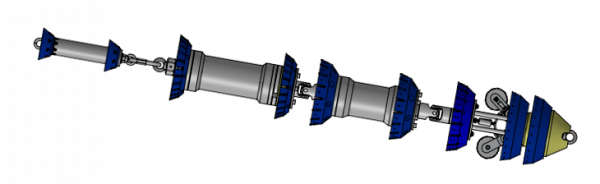

Since navigation by satellite, as commonly used in cars, is not possible from within a pipeline, an XYZ inertial measurement unit on board the ILI tool is required. It carries angular rate sensors and acceleration sensors for all three dimensions in order to track the pipeline course during inspection run. By means of above ground markers the inertial data can be referenced to the geographic coordinate system so they can be handled by the usual navigation and cartographic systems.

Key Advantages

- XYZ carries a high-end inertial system, available for pipeline diameter as small as 3”

- Since small and robust, it can be combined easily with any ILI tool

Typical Applications

- Combo with any other ILI tool. It contributes to build the extensive pipeline data base to include geographic coordinates for all girth weld, installations and features

- XYZ generates true extension maps and vertical profiles of the pipeline

- With known highly accurate recent elevation data of the pipeline’s right of way the depth of soil cover can be generated along the pipeline length

- In combo with GEO bends can be analysed accurately regarding angle, radius and bend direction. Mitre bends are identified

- Pipeline movement can be monitored with repeated XYZ runs comparing the subsequent data sets. Accuracy of +/- 0,1 m can be achieved

Availability Details

3P Services offers the XYZ beginning 2010. The recent high-end inertial system is available since 2019.

The XYZ can be run as stand-alone tool or fixed to any ILI. Standard or bi-directional configuration.

Smallest XYZ application is in 3” pipelines.

How can we help you?

Do you have any questions regarding our inspection technologies? Can we provide you with more information or support you with your projects?

Click here to contact us

Technology Overview

Click here to get an overview about our inspection technologies.