SRD Inspection by 3P Services

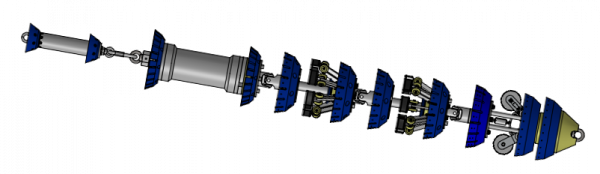

The Short Range Distance (SRD) is an innovative inspection system developed by 3P. It focusses on internal features at extremely high resolution. Different from other metal-loss technologies the SRD can work at significantly higher tool speed. It is well suited to detect pinholes down to 5 mm x 5 mm and size features as shallow as 0.5 mm. The surface of girth and longitudinal welds can be analysed for discontinuities.

Compact information about our SRD tools

This page gives you an overview about the following topics:

The Physical Background of SRD Inspection

The principle works on the interaction of a small permanent magnet and the change in its magnetic field if a ferritic body enters its vicinity. Though magnets are used here as well, the SRD has nothing else in common with MFL. While MFL requires massive magnets to achieve saturation within the entire pipe wall, the SRD works on a saturation level close to zero.

Individual SRD sensors are arrayed in groups of 8 embedded in a single sensor carrier, which is guided by an arm and distance controlled by wheels along the inner pipe surface.

Extended version SRD/GEO

This combo system has proven to be very helpful. Not only that it simply combines the SRD and GEO capabilities. In situations where smooth general metal loss is present the SRD sensor carrier arms will follow the (corroded) physical inner surface and leave the measurement of the depth of the general metal loss to GEO-sensors in the foot of the SRD-sensor carrier arm. SRD will then continue to search for pits and pinholes. The total depth of internal metal loss results from depth (GEO) plus depth (SRD).

Key Advantages

- Depth sizing accuracy is the better, the shallower a metal loss feature is

- A substantial number of sensors can be accommodated without interference

- Unaffected by high tool speeds, accelerations and decelerations

Typical Applications

- Detection and sizing of incipient shallow internal metal loss in new natural gas pipelines. By repetition: confirm efficiency of inhibitors.

- Measurement of internal layers and coatings (clads, CRA, epoxy coatings). Determines presence and thickness of layers, coatings and locations of disbonding from ferritic carrier pipe.

- More suitable than other metal-loss technologies for low pressure / low flow natural gas pipelines and slack line conditions in liquid pipelines.

Availability Details

3P Services offers SRD inspections since 2014, SRD/GEO since 2018.

Today the SRD equipment fleet covers tools from 8” to 48”. There is a broad variety of special tools, e.g. for multi-diameter inspections, tight bends (down to radius 1D), high speed, high pressure (up to 400 bar), high temperature (up to 120 °C), long distance and extended battery lifetime.

All SRD tool sizes can be configured for bi-directional operation.

SRD can be combined with other inspection technologies for combo tools.

How can we help you?

Do you have any questions regarding our inspection technologies? Can we provide you with more information or support you with your projects?

Click here to contact us

Technology Overview

Click here to get an overview about our inspection technologies.