Bi-Directional Inspection

Bi-Di Concept by 3P Services

In many pipelines, actually the older the more, there are no facilities to launch or receive ILI tools, or even the initial idea to have the pipeline inspected. If only one end is accessible, then a bi-directional operation is the way to go.

3P Services introduced the concept of free swimming bi-directional inspection tools to the industry more than 20 years ago. Since then, sophisticated tethered or self-propelled applications are no longer required in many ILI projects.

Compact information about our Bi-di inspection tools

This page gives you an overview about the following topics:

General information about Bi-Directional inspection

Generally, all ILI technologies offered by 3P can be used in bi-directional applications, even combo versions.

The basic idea is to have a launcher/receiver at the accessible end of the line, pump a tool into the line and then – at reversed flow – pump it back to the start position. This requires to have pumping capacities and sufficient volume (tank capacity) at both ends.

We also have extensive experience of other scenarios: pumping a tool with a liquid column into a high pressure gas line and using the gas pressure to push the tool and liquid back to launch position; pump in with gas against gas; pump in and pull out.

Practically speaking, it is a special process for our Clients, but it has turned out on many projects to be easier than expected. Careful co-operation between all involved parties prior to, during and after the inspection execution is essential.

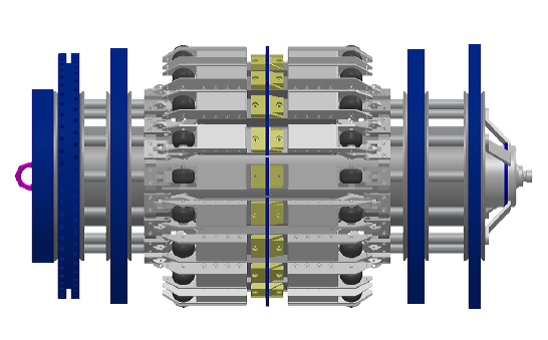

Bi-directional inspection tools require special design that affects various mechanical, sensor and electronic related elements. They must be able to run and inspect forward and backwards. With this technology 3P Services records measurements while traveling in both directions. Therefore, a double inspection coverage is achieved. This supports the data analysis process and brings a powerful boost to the confidence in the accuracy of the inspection data.

Key Advantages

- Generally no restriction to range or pipeline length

- No restriction to the number of bends present in the line

- Short radius bends, usually down to 1.5 D, and back to back bend combinations are not obstacles

Typical Applications

- Coastal tanker loading and unloading terminals where the offshore end of the pipeline ends on the sea floor

- Offshore flowlines, where platform risers may not be passed by mechanical steel bodied tools (e.g. due to sensitive flexible risers)

- Typically in all pipelines where access to one end is very limited.

Availability Details

3P Services offers bi-directional free-swimming inspections since 1999.

Today the equipment fleet for bi-directional applications covers tools from 3” to 48”. There is a broad variety of special tools.

Bi-directional combo tools can be assembled with basically all inspection technologies offered by 3P.

How can we help you?

Do you have any questions regarding our inspection technologies? Can we provide you with more information or support you with your projects?

Click here to contact us

Technology Overview

Click here to get an overview about our inspection technologies.